DOP series (Piston pump)

GLD series (Oil Sealed rotary vacuum pump)

VDN series (Oil Sealed rotary vacuum pump)

PVD –series Oil Sealed rotary vacuum pump

VSN-series Oil Sealed rotary vacuum pump

NB series Booster Pump

NRL series Dry Pump

YM pump Unit

Vacuum gauge

Option parts and vacuum oil

NOC series (Oil cleaner)

NWS series (Oil water separator)

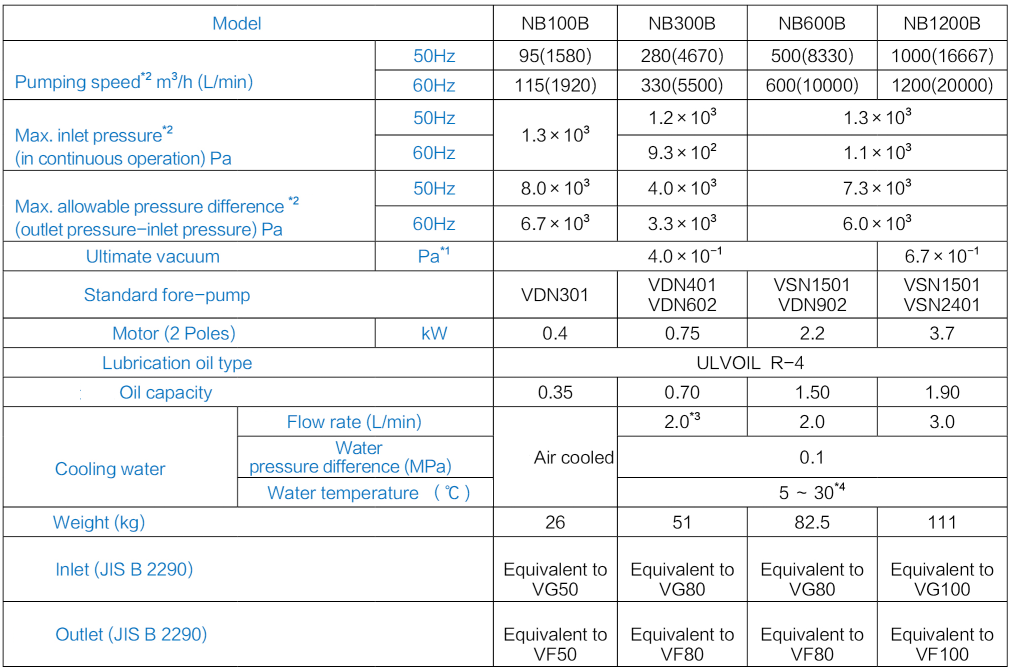

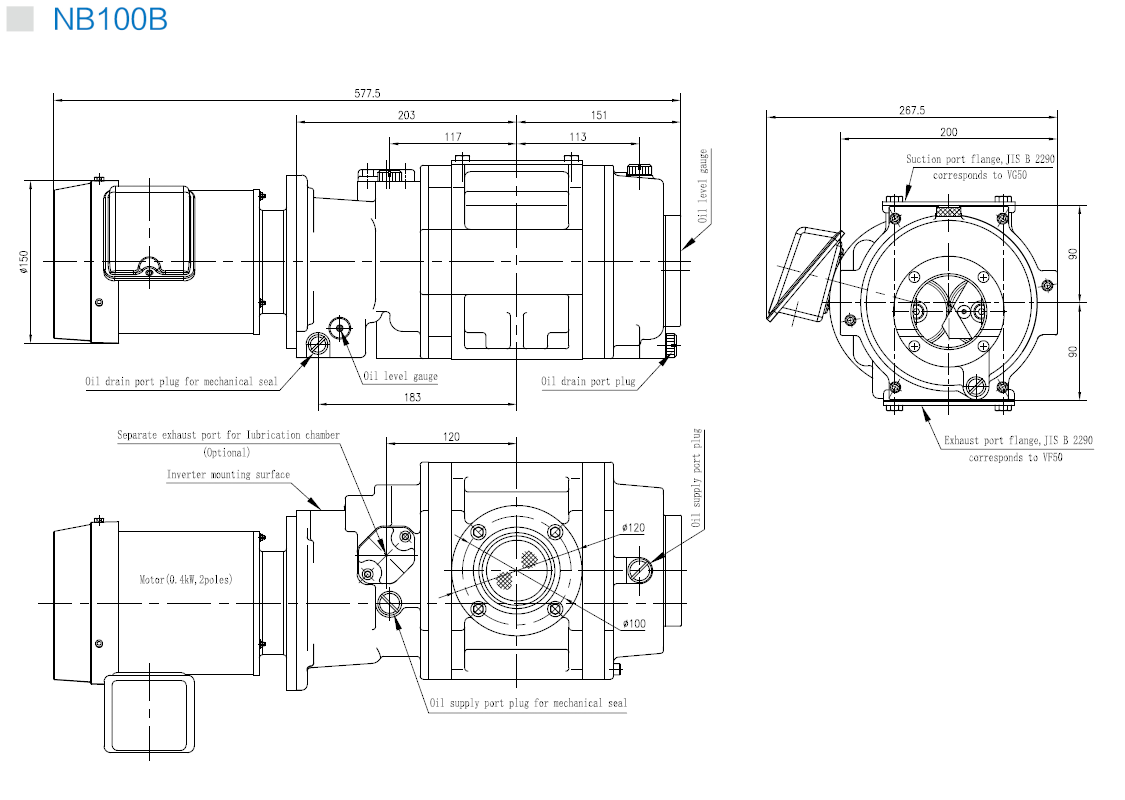

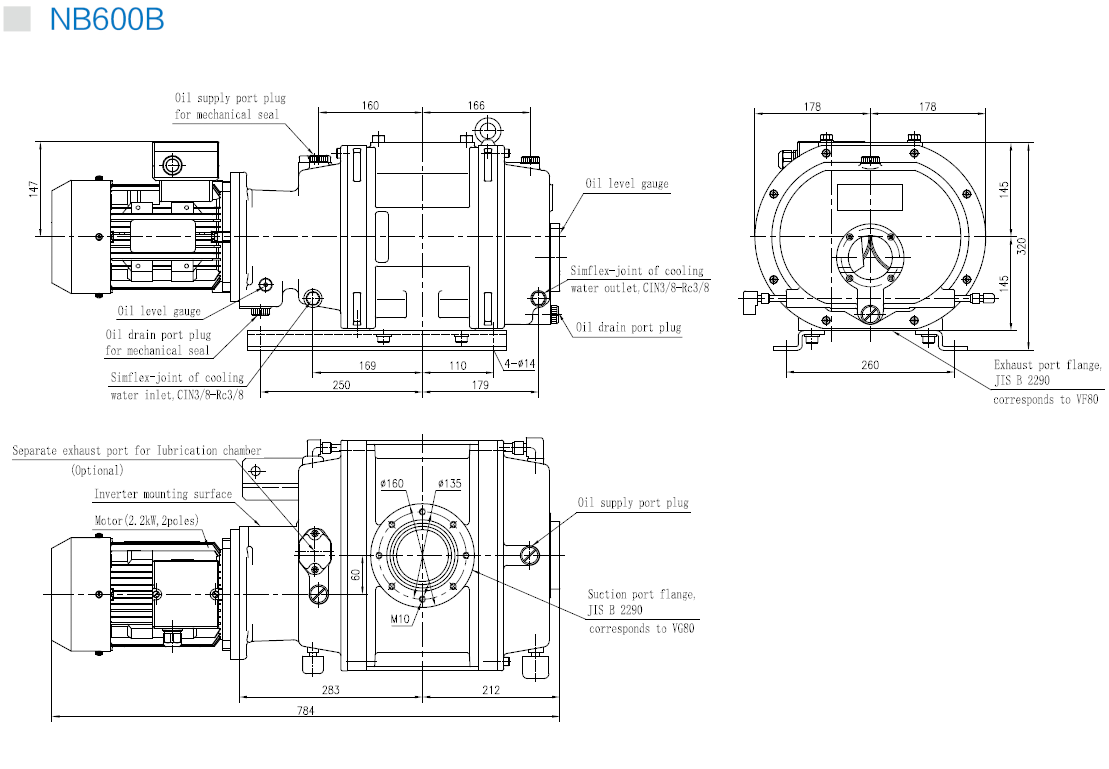

NB100B-NB1200B Booster Pump

-

Features

Oil-free

Since no lubricating oil is used in the casing chamber, stable performance is realized even when evacuating water vapor or solvent vapors.

Operation at high inlet pressure

If a motor larger than the standard motor is installed, the pumps are sufficiently applicable to systems having high gas loads, such as CO2, laser process.

Applications

• Illuminate, electronics optics, semiconductor.

• Evaporation, sputtering, ion plating, liquid crystal injector.

• Vacuum drying, freeze drying, vacuum degassing.

• Vacuum heat treatment furnaces, sintering furnaces, brazing furnaces.

• Analytical instrument, leak testers, CO2 laser equipment vacuum dryers.

* 1 This value is measured by the Pirani vacuum gauge. It is approx. 4.0×10-2 Pa (NB1200B is 6.7×10-2 Pa) when a McLeod vacuum gauge is used.

* 2 This value changes depending on the performance of the fore pump. The above data is obtained when the pump is used in combination with a standard fore-pump.

* 3 Air cooling will do when the pressure is lower than 530 Pa. Water cooling is required in continuous operation at a pressure higher than 530 Pa.

* 4 The temperature of inlet port cooling water must between 5~30℃.The pump is prohibited to be used in dewy environment or low temperature environment of the cooling water.

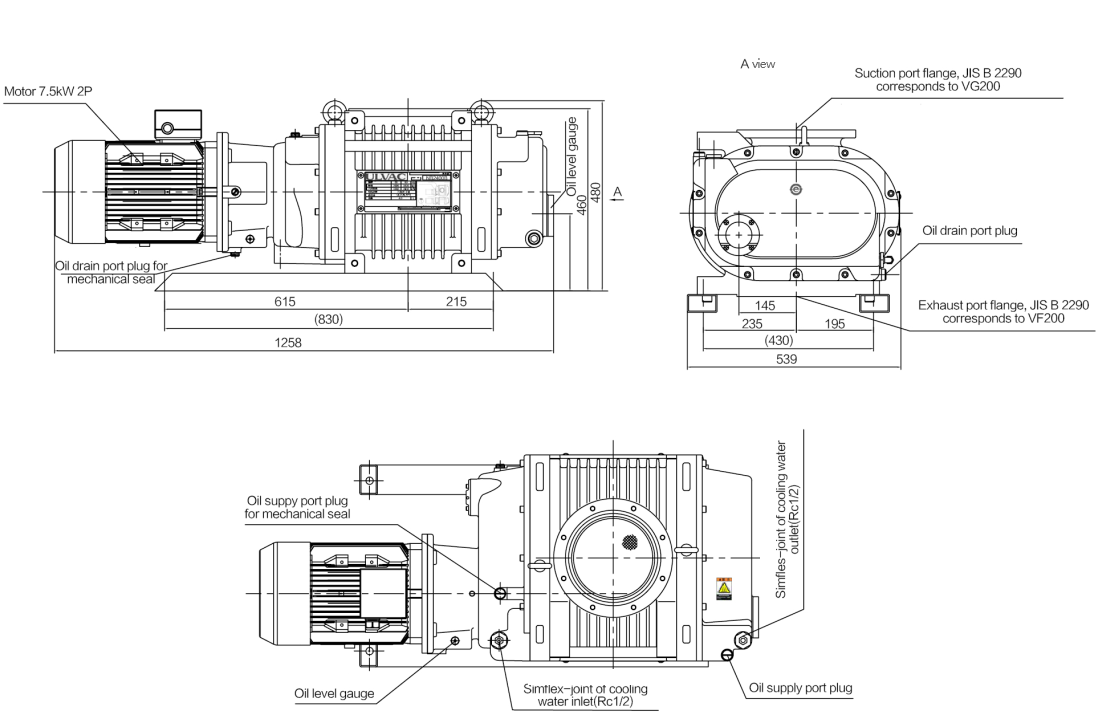

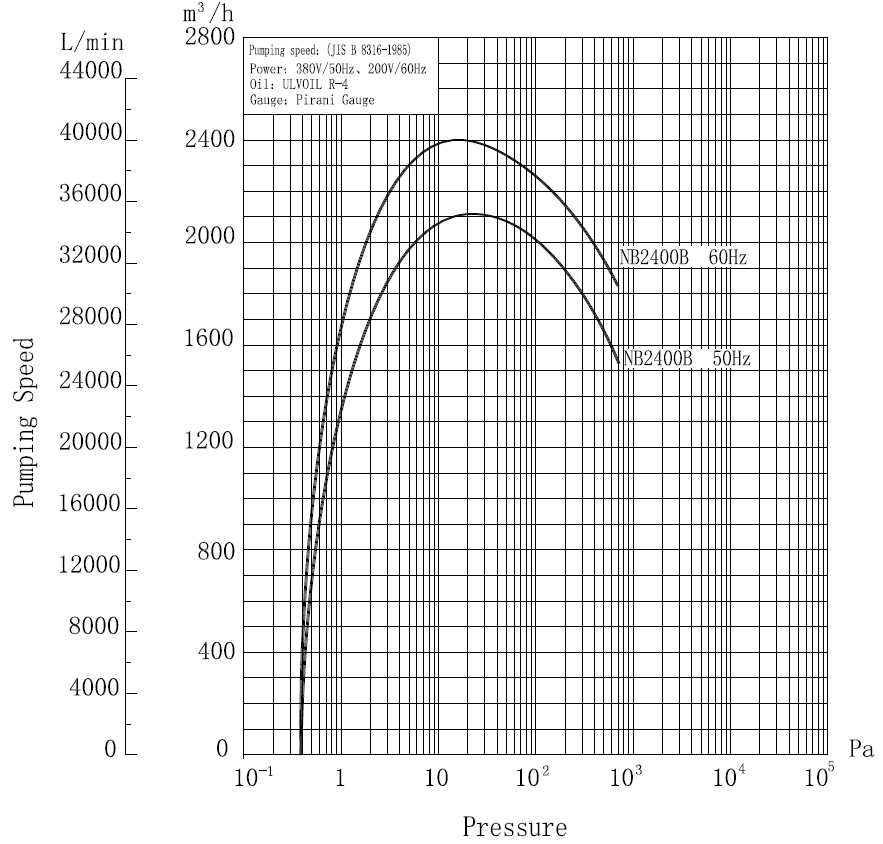

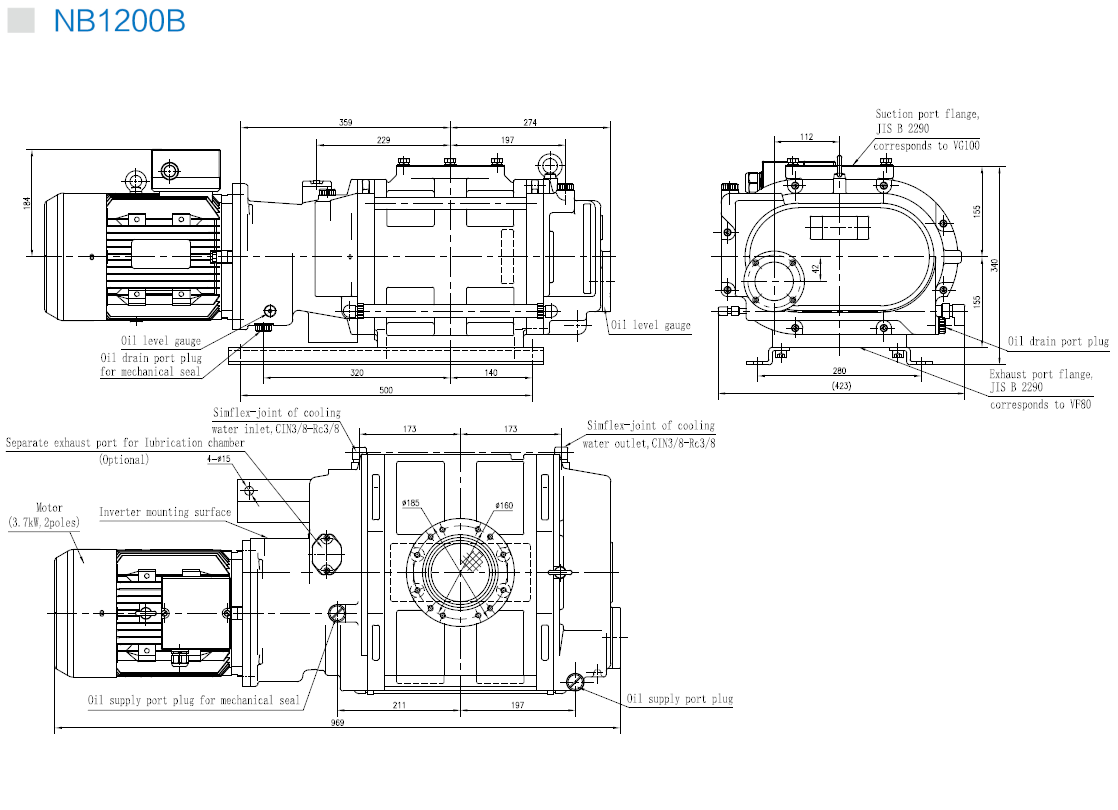

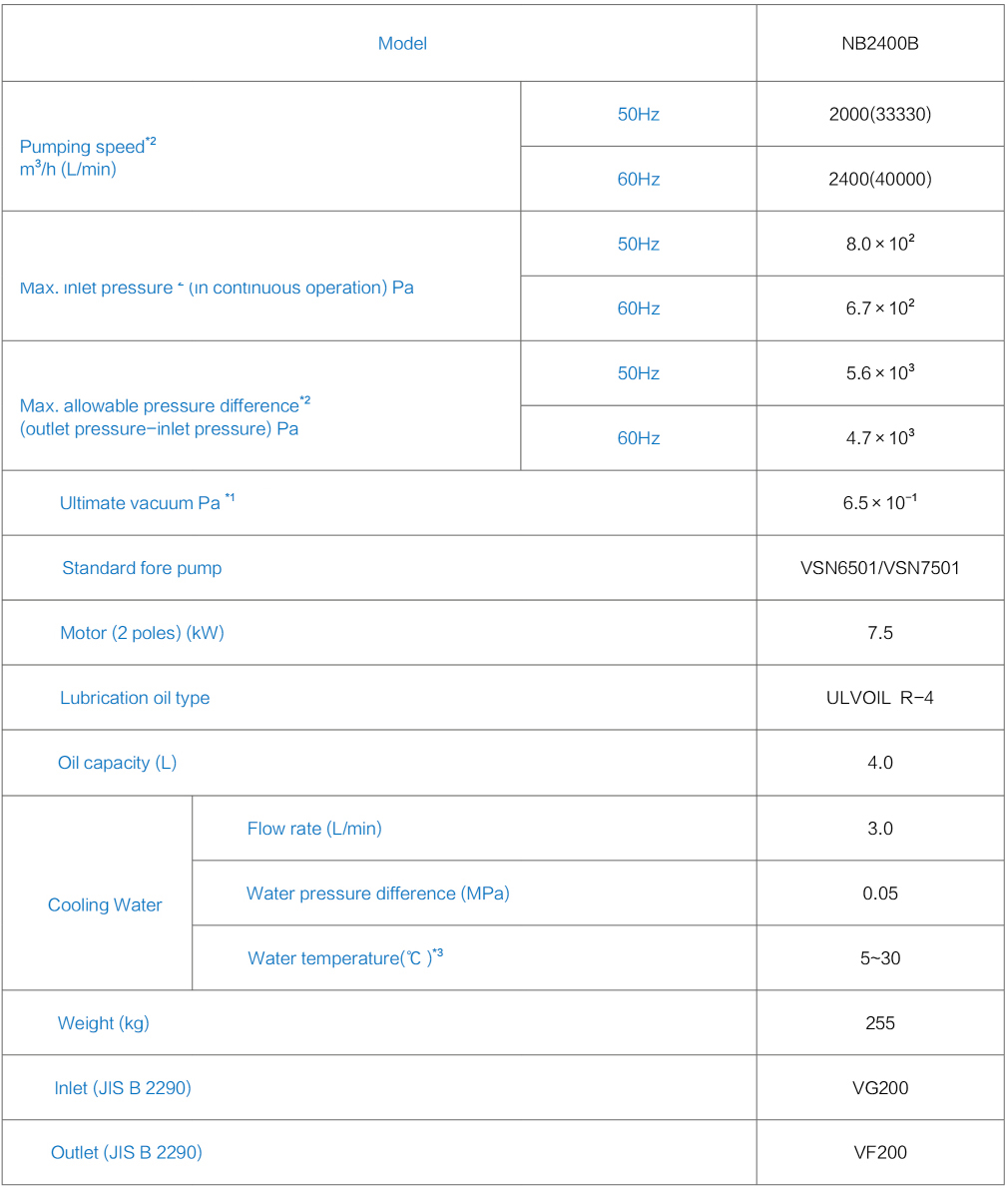

NB2400B Booster Pump

-

Features

Oil-free

Since no lubricating oil is used in the casing chamber, stable performance is realized even when evacuating water vapor or solvent vapors.

Special surface treatment

• The surface of the main components is hard oxidized to improve corrosion resistance and reduce internal damage of the pump body.

• This feature is optional and the surface of the standard is not processed.

Configure the inverter to shorten the exhaust time

• After the inverter is configured, it is started simultaneously with the rough pump,which effectively shortens the exhaust time compared with the standard pump.

• This accessory is optional and the standard pump is not configured.

Applications

• Evaporation, sputtering, ion plating, liquid crystal injector.

• Vacuum drying, freeze drying, vacuum degassing.

• Analytical instrument, sealing device.

• Vacuum heat treatment furnace, dissolution furnace.

• Various other vacuum devices.

* 1 This value is measured by using a Pirani vacuum gauge. It is approx.6.5×10-2 Pa when a Mcleod vacuum gauge is used.

* 2 This value changes depending on the performance of the fore pump. The above data is obtained when the pump is used in combination with a standard fore pump.

* 3 The temperature of inlet port cooling water must be 5~30℃. Keep the environment that does not cause dew formation when the cooling water temperature was lower.