DOP series (Piston pump)

GLD series (Oil Sealed rotary vacuum pump)

VDN series (Oil Sealed rotary vacuum pump)

PVD –series Oil Sealed rotary vacuum pump

VSN-series Oil Sealed rotary vacuum pump

NB series Booster Pump

NRL series Dry Pump

YM pump Unit

Vacuum gauge

Option parts and vacuum oil

NOC series (Oil cleaner)

NWS series (Oil water separator)

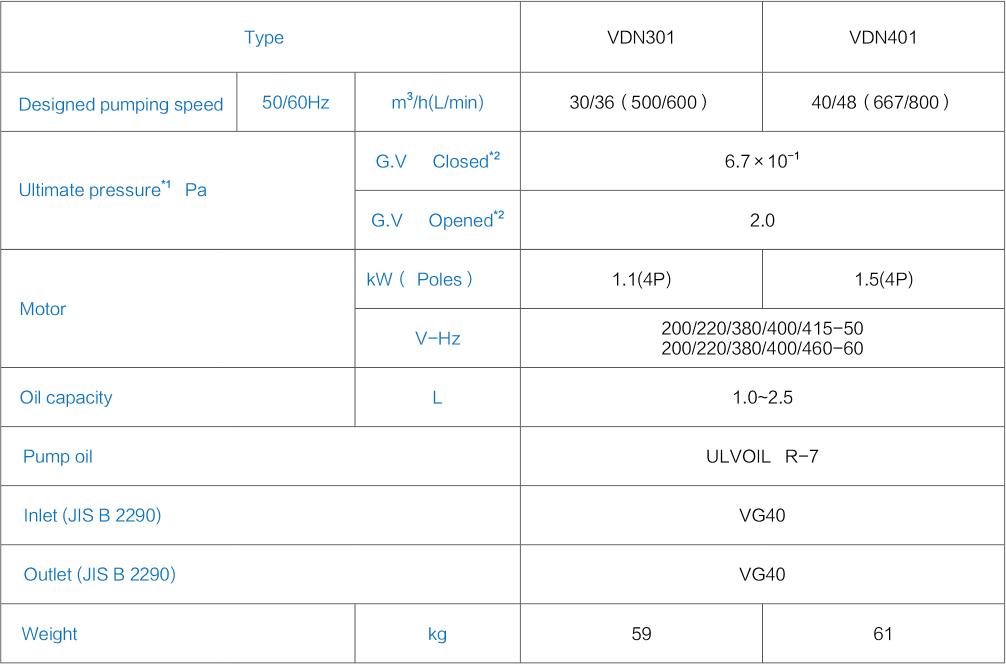

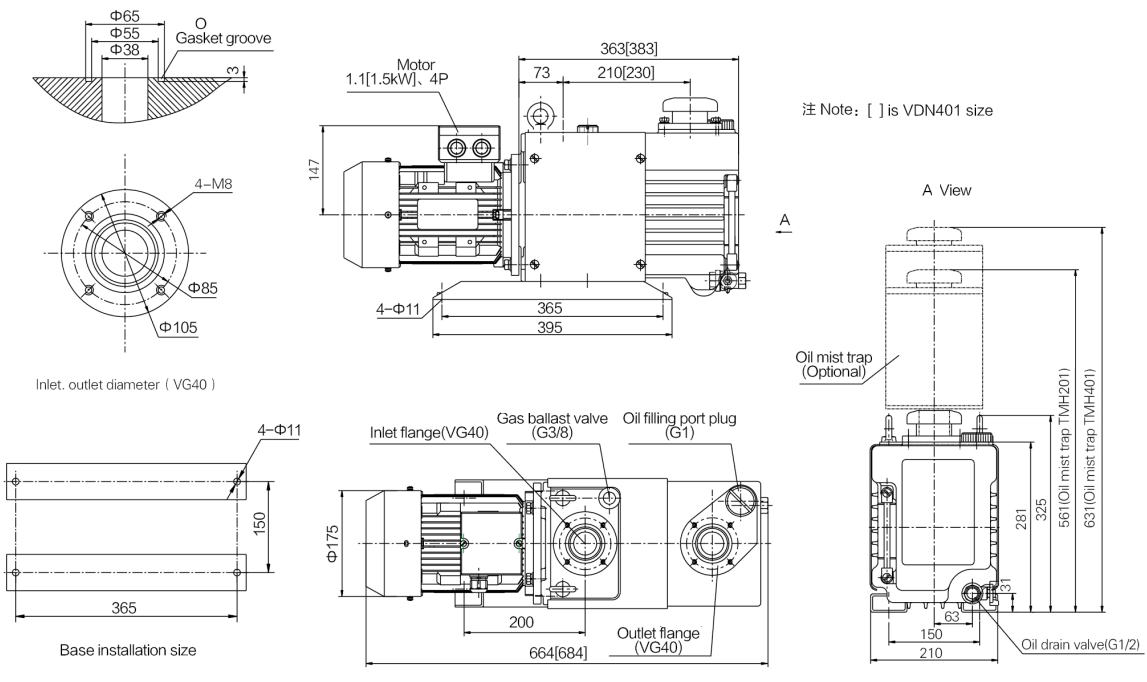

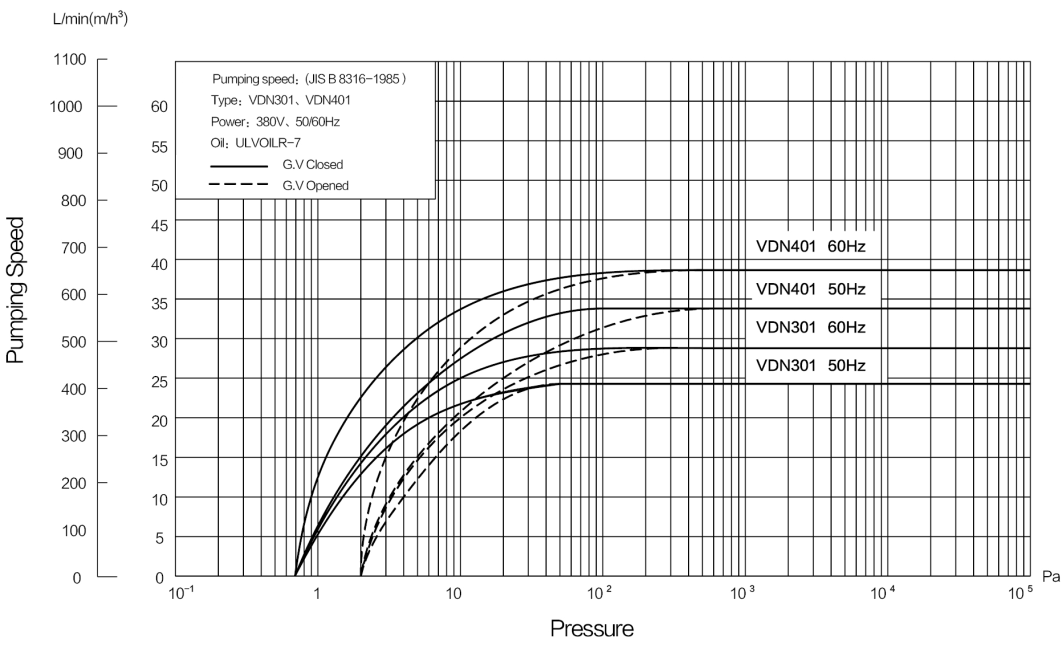

VDN301 / VDN401 Oil Sealed rotary vacuum pump

-

Features

Low noise

Optimized design achieved quiet running.

Easy maintenance

Pump body can be removed without disconnecting the inlet vacuum pipes.

Checking, adding and changing oil are done at the same side of the pump to facilitate greater ease in performing routine maintenance and inspection. A variable oil volume is adopted to extend the complementary time of oil.

Forced oil circulation system ensures stable pumping speed around atmospheric pressure

When equipped with optional oil mist trap and oil return mechanism, these pumps can run continuously at pressures equal to or below atmospheric pressure.

Applications

• Evaporation, sputtering and ion plating.

• Gas substitution, back-filling and vacuum insulation.

• Vacuum drying, freeze drying, vacuum degassing.

• Analytical instruments and leak testers.

• Vacuum packing, vacuum adsorption and transport,vacuum molding and vacuum casting.

* 2 G.V is abbreviates by gas ballast valve.

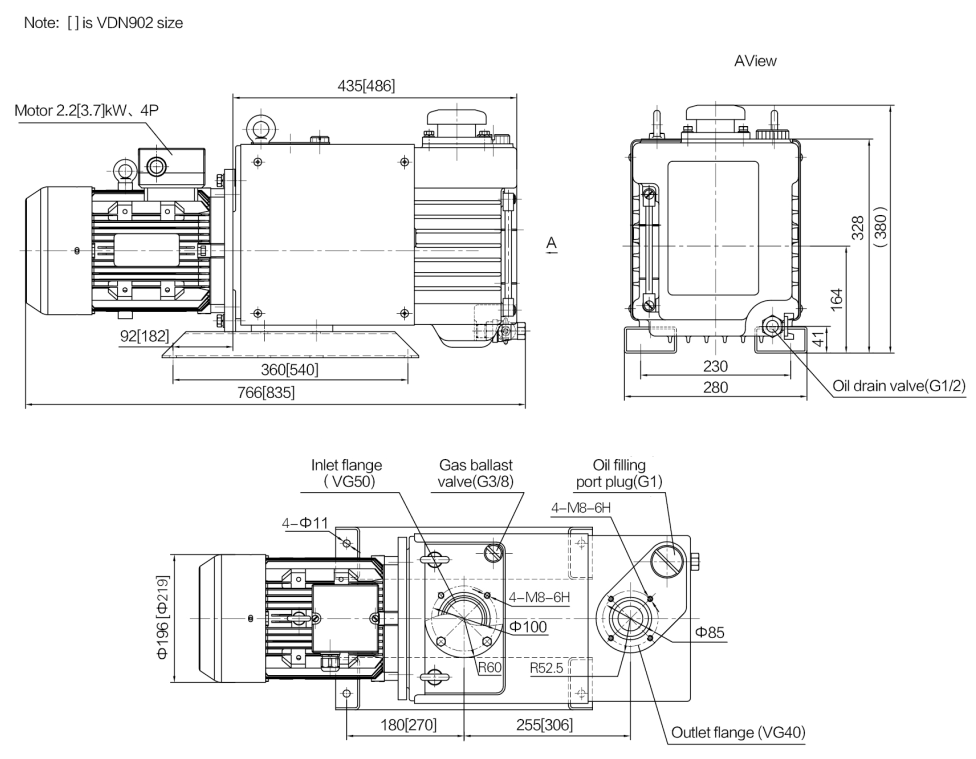

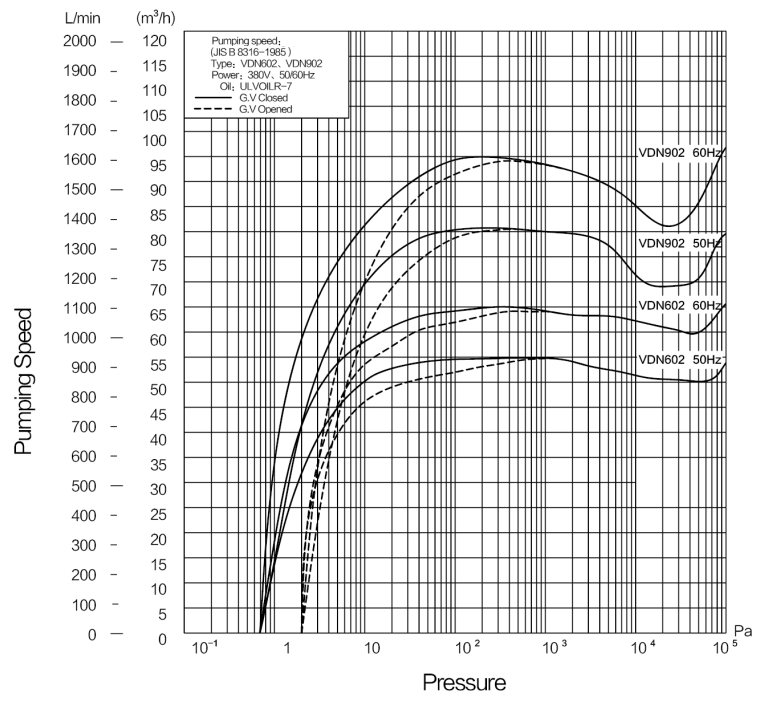

VDN602 / VDN902 Oil Sealed rotary vacuum pump

-

Features

Low noise

Optimized design achieved quiet running.

Easy maintenance

Pump body can be removed without disconnecting the inlet vacuum pipes.

Checking, adding and changing oil are done at the same side of the pump to facilitate greater ease in performing routine maintenance and inspection. A variable oil volume is adopted to extend the complementary time of oil.

Forced oil circulation system ensures stable pumping speed around atmospheric pressure

When equipped with optional oil mist trap and oil return mechanism, these pumps can run continuously at pressures equal to or below atmospheric pressure.

With CE certification

Applications

• Evaporation, sputtering and ion plating.

• Gas substitution, back-filling and vacuum insulation.

• Vacuum drying, freeze drying, vacuum degassing.

• Analytical instruments and leak testers.

• Vacuum packing, vacuum adsorption and transport,vacuum molding and vacuum casting.

* 1 Measured with a Pirani gauge (Approx. 6.7×10-2Pa when measured with a McLeod vacuum gauge).

* 2 G.V is abbreviates by gas ballast valve.